As an avid caffeine enthusiast, I distinctly remember when Coke Zero burst onto the soda scene.1 It was another salvo in the Cola wars between Coca-Cola and Pepsi, making a notable impact as a diet soda that wasn’t explicitly marketed as one.2 With new formulations, rebrandings, and vying for consumers’ minds and dollars, it’s often hard to keep track of product and industry evolutions and the underlying reasoning of why they’re happening.

You may be surprised to learn that we’re in the midst of another significant change. The refrigerants that provide cooling are on the brink of a metamorphosis.

Refrigerants! What Are They Good For?

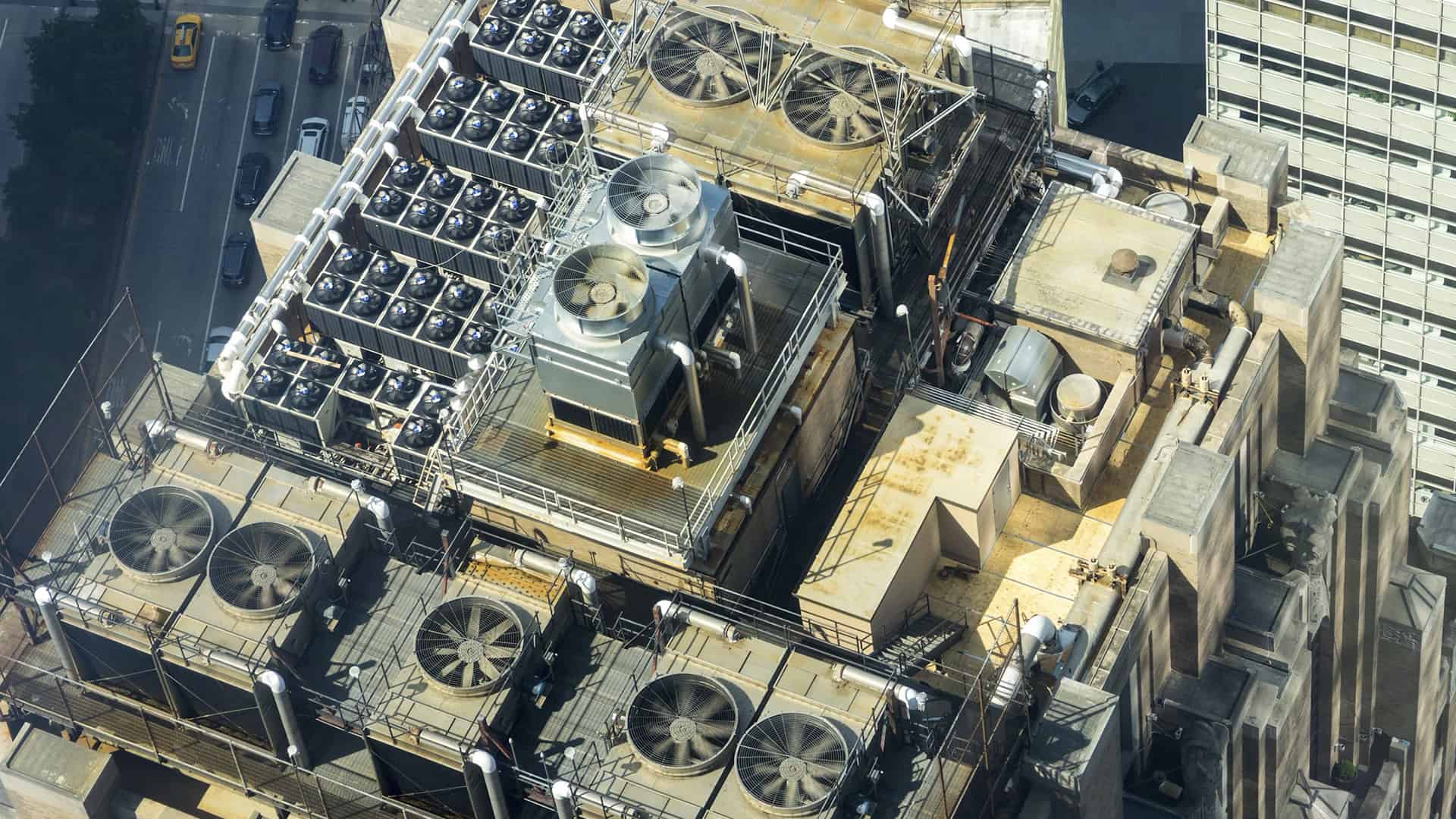

Much of the cooling in our modern world uses various refrigerants to move heat around. It’s in our cars, homes, and workplaces, for the most part. Some regions, such as the American Southwest, use evaporative cooling, spraying water into the air to evaporate in the dry heat and thereby cooling the surrounding air. But this method works best in hot, dry areas.3

Newer technologies, such as thermo-electric cooling, pass electricity through a specialized chip, which generates heat on one side and removes it from the other.4 However, thermo-electric coolers are limited in efficiency and output, especially as compared to refrigerant systems. While refrigerant-based systems work better than the alternatives, there is a problem with them.

Spoiler alert! The problem is with the refrigerants themselves. Although the systems include copper tubing, metal fins for heat transfer, a compressor, and valves, the refrigerant does the bulk of the work by transporting heat where it’s needed. You might imagine all sorts of gnarly chemicals—and you’d be mostly correct. But in this context, refrigerant is simply a fluid that moves heat around, shifting from gas to liquid primarily by using boiling and condensing temperatures and pressures.5 Depending on the conditions, air or water could be used as a refrigerant, but most commonly, refrigerants are human-made.6

The Problem with Refrigerants

The issue with refrigerants arises when they escape, leak, or release into the atmosphere. As technology evolves and we become aware of their environmental impacts, we’ve undergone several phase-outs of refrigerants. Typically, these phase-outs start with a ban on manufacturing new equipment using phased-out refrigerants. Then, there are restrictions placed on producing new refrigerants. Complicating matters is that most replacements aren’t simply interchangeable (“drop-in” replacements) and often require new or modified equipment to properly function.

One of the original refrigerants was ammonia, which was surprisingly effective for cooling. The usage of ammonia refrigeration systems continues today, notably in hockey rinks and breweries. However, as anyone who has encountered it in cleaning solutions knows, it’s corrosive and has a strong odor. It was later replaced by non-toxic chlorofluorocarbon (CFC) based refrigerants. Freon, or R-12, was a commonly used refrigerant in cars and central HVAC systems. Sadly, it had the nasty habit of eating holes in the ozone layer.7 By the mid-90s, R-12 was on its way out.

The same year that brought us Friends, the original PlayStation, and the founding of Amazon, a new refrigerant called R-22 entered the scene. R-22 belonged to a new breed of refrigerants known as hydrochlorofluorocarbon (HCFCs). Compared to its predecessors, it had a significantly lower potential for ozone depletion, marking a notable improvement. However, it still contributed to ozone depletion, and the Montreal Protocols eventually phased it out. Under these requirements, R-22 was sunset in 2010.8

R-410A, the new hotness, arrived with a clean slate—it had no impact on the ozone, a refreshing change from R-12 and R-22.9 However, its higher pressure compared to R-22 required the development of a new generation of cooling equipment capable of handling it. Despite its ozone-friendly nature, R-410A came at a cost—it had a much greater potential for contributing to global warming, about 20% more. As the public awareness of climate change impacts grew, its days also became numbered.

The Dawning of a New Age

As I write this, the current generation of human-made refrigerants is on the way out. The American Infrastructure and Manufacturing Act (AIM) of 2020 introduced a maximum limit on the global warming potential (GWP) of refrigerants. With a maximum impact of up to 700 times greater than carbon dioxide, almost all currently used refrigerants won’t make the cut. Even those meeting the maximum might not last long as the world pursues climate change goals. Legislation or market forces will likely introduce a lower maximum GWP soon.

In the short to medium term, Hydrofluroolefins (HFOs) represent the new wave of refrigerants. This “fourth generation” of refrigerants boasts zero ozone depletion potential and low GWP. But, as always, this performance comes with a trade-off. HFO refrigerants are classified as “A2L,” indicating a degree of flammability that raises concerns for fire codes and building safety. Although they do not easily ignite.10 Additionally, HFO refrigerants tend to break down into PFAS, a newer item of concern, commonly called “forever chemicals,” with unknown impacts.

Given these challenges, the future of refrigerants is uncertain. While HFOs will likely remain in use for some time, the fifth generation of refrigerants may soon emerge. Alternatives such as carbon dioxide (R-744), propane (R-290), and the original refrigerant, ammonia, are being considered. Each has drawbacks: carbon dioxide requires very high pressures, propane is flammable, and ammonia is toxic.

What Does the Future Hold?

Throughout the evolution of refrigerant strategies, there have always been trade-offs. From the days of using ammonia to today’s methods, each generation has seen a decrease in system efficiency. The increasing operational pressures required for newer generations also mean more energy is needed to run the systems.

One potential solution is to reduce our reliance on air conditioning whenever feasible. However, the industry’s shift toward heat pump technology, which utilizes refrigerants as heating sources instead of fossil fuels, complicates this approach. Designing buildings with reduced heating and cooling needs from the start could help minimize the environmental impacts of refrigerants.

- Currently called Coke Zero Sugar. Why they went away from the black cans is beyond me. ↩︎

- See also: Crystal Pepsi, Diet Coke with Lime, Vanilla Coke, Pepsi Blue, and others. ↩︎

- And almost not at all in hot, humid areas. Spraying all that water just makes it more humid in these areas. ↩︎

- The underling physics is the Peltier effect. It’s used in those USB powered drink heaters and cookers, computer heat sinks, and satellites. ↩︎

- People smarter than I mapped these out into “Vapor Pressure Curves.” Related, this vapor pressure phenomenon is why the boiling point of water in the Rocky Mountains isn’t the same as it is at sea level. ↩︎

- Air and water aren’t ideal refrigerants. For HVAC systems, the pressures and temperatures for these aren’t commercially viable. ↩︎

- Featured in the ‘90s era cartoon “Captain Planet” in the episode titled, “Ozone Hole.” ↩︎

- Technically, you can still import R-22, but no major manufacturer creates new equipment using it. The imported R-22 is generally used for keeping older equipment running. ↩︎

- R-410A is a Hydrofluorocarbon (HFC) refrigerant, for those keeping score. ↩︎

- The letter indicates the toxicity and the number flammability. A = non toxic, B = toxic. 1 = No flame propagation, 2 = lower flammability; 3 = higher flammability. Bafflingly, 2L is between 1 and 2. ↩︎