Retail brands today face a common dilemma: how to reduce construction costs without compromising the customer experience that defines their brand. Whether it’s a flagship store, a neighborhood bank branch, or a quick-service restaurant, retail spaces must be both cost-conscious and brand-consistent to compete effectively.

That’s where value engineering (VE) comes in—not just as a cost-cutting tool, but as a strategic design approach. It identifies opportunities to reduce cost, improve constructability, and elevate the customer experience, all while preserving the original design intent. At Little, we help national retailers rethink their prototypes with this mindset, ensuring every design decision supports both financial performance and long-term brand equity.

REDUCING CONSTRUCTION COSTS WITHOUT COMPROMISING THE BRAND

Value engineering is often misunderstood as a series of trade-offs, where costs are lowered at the expense of design. In reality, with the right approach, it becomes a strategic opportunity to reinforce brand priorities while achieving measurable savings.

“How can we reduce costs while maintaining our brand standards?”

As construction and operational costs continue to rise, retail leaders are increasingly asking: “How can we reduce costs while maintaining our brand standards?”

It’s not as simple as swapping materials or cutting scope. The real challenge lies in knowing where to focus—what to adjust, what to preserve, and how to optimize without sacrificing the quality and consistency that consumers expect.

Little approaches this as a design challenge. The process begins by assembling a transdisciplinary team to identify high-impact opportunities—strategic “big moves” that drive significant cost savings while protecting the brand experience.

Listening is at the core of this approach. Rather than offering trend-driven or preconceived solutions, the team begins with a deep understanding of each client’s business model, brand vision, and customer expectations. This foundation ensures that every recommendation is tailored, purposeful, and aligned with long-term business goals.

ALIGNING ON WHAT DOES—AND DOESN’T—DEFINE THE BRAND

Successful value engineering efforts begin with clarity around what truly defines the brand. Little facilitates visioning sessions to gain a deep understanding of each client’s identity, priorities, and goals. As part of this process, the team presents an interpretation of the brand back to the client, confirming alignment and distinguishing which elements are essential and which offer flexibility.

This collaborative approach ensures that every recommendation is grounded in a shared understanding. By investing the time to listen, learn, and validate early, Little delivers cost-saving solutions that also protect brand integrity.

WHERE ARE THE BIG OPPORTUNITIES TO SAVE?

In early concept development, Little leads collaborative brainstorming sessions to identify design strategies that generate measurable cost savings. These sessions invite client input in real time, ensuring solutions are shaped around both operational goals and construction efficiencies.

For a recent VE exercise performed for a confidential client, we were asked to reduce the construction cost by 15%. By utilizing this process, we were successful in not only hitting the goal but surpassing it by an additional 5-10%.

Recurring opportunities for savings tend to fall into six key areas:

- Reducing building square footage

- Lowering overall building height

- Reorganization of program elements

- Elimination of non-essential program components

- Optimizing glazing

- Substituting materials strategically

Each of these strategies offers a targeted way to reduce costs while preserving the core brand experience. Let’s explore in more detail.

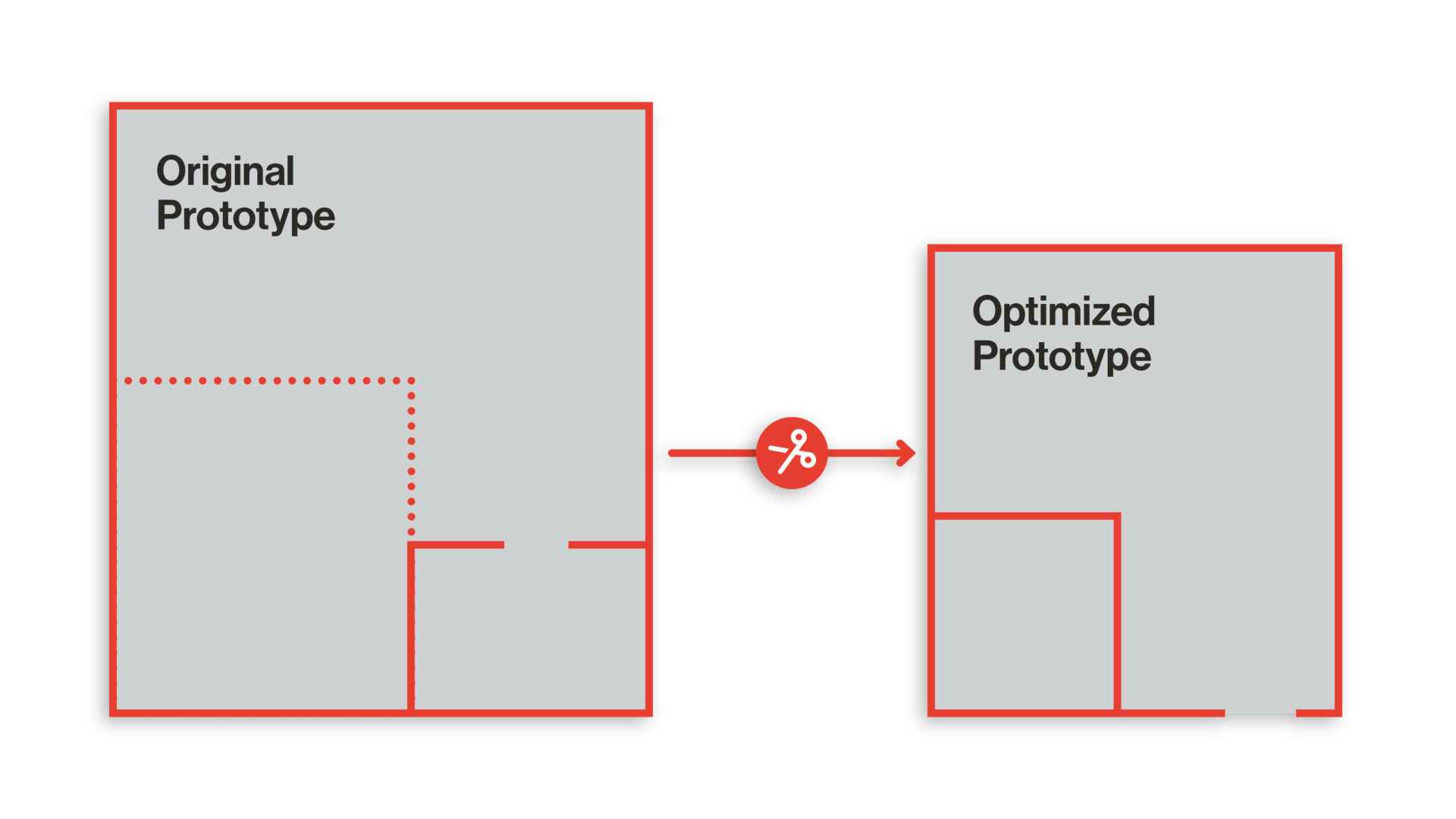

RIGHT-SIZING THE BUILDING

One of the most immediate ways to reduce construction costs is to minimize overall square footage. Even modest reductions can lead to significant savings. For example, eliminating just 200 square feet at an average $600 per square foot rate can reduce costs by $120,000.

These reductions are achieved through targeted design optimizations. Drawing on experience across multiple retail formats, Little identifies areas where space can be minimized or eliminated altogether. In some cases, building size and occupancy thresholds remove the need for systems like fire sprinklers, eliminating not only that scope of work (design, permitting, and trade coordination), but also the associated square footage needed for the riser room that supports it.

Another common opportunity is rethinking oversized conference rooms. While these spaces have become more prevalent in many retail environments (especially in bank branches), scaling them down can reduce the need for additional entrances, plumbing, or restrooms needed to support that function, contributing to a more efficient footprint without sacrificing functionality.

SHRINKING THE STRUCTURE, NOT THE EXPERIENCE

In addition to reducing footprint, lowering a building’s overall height can also yield meaningful savings. By reevaluating the placement of key systems, Little often identifies opportunities to reduce structural height by several feet without impacting functionality. For one particular client, reconfiguring building systems enabled a height reduction of 3 to 4 feet, minimizing material use and structural demands without compromising functionality.

SMARTER PROGRAM LAYOUTS

Reorganizing key functional areas can lead to a more efficient footprint and lower construction costs. One effective strategy is consolidating plumbing functions near the most likely utility tie-in point. This reduces the number of plumbing walls and the overall length of piping required.

These adjustments simplify system distribution, reduce unnecessary circulation space, and support broader goals for space optimization and cost reduction.

SITE EFFICIENCY

Site design—particularly the civil scope—can account for a significant portion of construction costs. As customer behaviors evolve, drive-thru demand has become more varied across retail sectors, prompting many brands to reassess how these areas are designed and deployed.

For a recent exercise we did for a food service client, we noticed that the parking counts were significantly over what is required by the jurisdiction. We discovered the ability to reduce the number of parking spaces by half, which drastically reduced the site work cost.

GLAZING ADJUSTMENTS

After addressing primary cost drivers, Little turns to secondary opportunities where targeted design adjustments can deliver meaningful savings. One such area is the building envelope—specifically, glazing.

Glazing can significantly impact both material and energy costs. Reducing the overall glazing area is often the first step. Additional savings can be realized by using manufacturer-standard sizes, which are more readily available and cost-effective. Wherever appropriate, curtain wall systems are replaced with standard storefront systems to further reduce complexity and expense without compromising design intent.

STRATEGIC MATERIAL SUBSTITUTIONS

Material changes don’t have to be dramatic to make an impact. Rather than overhauling the entire exterior palette, Little looks for subtle, strategic modifications that reduce costs while maintaining design integrity.

These adjustments often involve simplifying detailing or minimizing the number of systems and trades required, streamlining both construction and coordination. Thoughtful substitutions like these can preserve the overall design character while supporting project budgets and schedules.

GETTING TO MARKET FASTER AND SMARTER

The final step in Little’s value engineering process involves integrating proposed options into a schematic design package, enabling pricing partners to compare modifications against the current prototype.

Working in close collaboration with architecture, engineering, and construction teams, the general contractor develops estimated cost savings for client review. This gives stakeholders the clarity and flexibility to implement the solutions that best align with their goals, allowing the project to move forward with confidence and efficiency.

IT’S NOT ABOUT COMPROMISE. IT’S ABOUT CLARITY.

True value engineering isn’t about doing less. It’s about focusing more on what creates value for your customers, what defines your brand, and what drives performance. With the right design partner, it’s possible to build smarter, not smaller.

If your team is rethinking your prototype strategy, let’s talk about how to lower build costs—without lowering expectations.