For more than 150 years—from the early 1800s through the 1980s—cotton apparel was big business, and the Carolinas wore it well. Once home to a significant share of the U.S. apparel industry, mill towns across the region thrived with pride, sending their goods across the county and around the world. Today, apparel remains a major manufacturing and retail sector. But influence has shifted—with waves of global production washing back onto our shores.

Recently held in Charlotte, NC, Shop! Marketplace was an occasion to dig into the rich topic of regenerative design principles—especially the concept of a circular economy in the apparel industry. I had the pleasure of moderating a session on this very topic, featuring two insightful speakers: Mark Messura, SVP of Global Supply Chain Marketing at Cotton Incorporated, and Eric Henry, President of TS Designs. Together, they walked us through the journey of cotton from “ag to bag” (i.e., from farm to finished product). The session, Dirt to Shirt: Cotton’s Resurgence Weaves Regenerative Futures, highlighted how cotton is making a comeback and how local participation is key to building a more sustainable, circular future for the industry.

Our talk began with a local retail story of how the garment industry blanketed the Carolinas region. We grow the cotton, reap it, gin it, spin it, weave it, knit it, finish it, cut it, sew it, print it, dye it, pack it, sell it, ship it, sell it again… and then you and your neighbor, buy it. After that, a new micro-cycle begins: we wear it, wear it out, outgrow it (physically, emotionally, or stylistically), recycle it, or compost it. As Eric’s trademark says, Dirt to Shirt™.

WHEN THE SHIRT ON YOUR BACK PUT FOOD ON THE TABLE FOR NEARLY 1 MILLION FAMILIES

In 1994, the Carolinas had a population of about 10 million. That same year, the North American Free Trade Agreement—better known as NAFTA—went into effect. Designed to eliminate trade barriers between the U.S., Mexico, and Canada, the agreement opened the door for companies to move manufacturing operations to countries where labor was cheaper. While it boosted some sectors, it had a devastating impact on the U.S. apparel industry.

In the Carolinas, decades of domestic manufacturing began to unravel. Nearly 10% of the population lost their jobs. When you factor in family members and communities affected, the total impact grew to around 2.6 million people—roughly 1 in 4 residents. Domestic apparel production, which once accounted for 98% of what Americans wore, has dropped to just 2% today.

The losses didn’t stop at the mills. Entire ecosystems built around the apparel industry—including retail design teams that supported giants like Sara Lee, VF Corp, and Burlington Industries—were also negatively impacted. These companies powered hundreds of retail stores, in-store displays, packaging materials, and advertising, all of which were hit hard as production and investment shifted overseas.

WHAT IS REGENERATED CAN BECOME REGENERATIVE

All this history helps set the stage for a bigger idea: what’s regenerated can become regenerative. Today, retail brands are more interested than ever in building stores as responsibly as possible. And by “responsibly,” we mean sustainably—striking a balance between growth and renewal.

As designers, we contribute by constantly striving to create retail spaces that combine efficiency with longevity. That means choosing fixtures and materials that are both cost-effective and durable, sourcing thoughtfully, designing graphics with purpose, and using packaging that reduces more waste than it creates.

The result? A beautiful store, often filled with products from across the globe—but built with sustainability in mind.

Still, any meaningful conversation about sustainable retail has to go beyond the shop itself. We also need to consider the sustainability of the products moving through it.

THE CIRCULARITY OF COTTON

That’s why cotton—according to Mark Messura of Cotton Incorporated—is such a compelling case. It’s not only natural and renewable, but it also has the potential to be perfectly circular. And the industry, he says, is making exciting progress toward that goal.

Cultivation

It starts with growing high-quality raw materials using regenerative farming practices—such as no-till methods (e.g., without discing or plowing), drought-resistant GMO varieties, and ongoing innovation in lab-grown techniques. The goal is to reduce chemical use and irrigation wherever possible.

Construction

Then comes production: unbleached and organic cotton fabrics are sewn with cotton thread and styled with natural dyes. Just-in-time order fulfillment helps minimize waste by producing only what’s needed.

Composting

Composting brings the Dirt to Shirt concept full circle. Cotton sewing thread allows garments to fully break down. When fabrics are unbleached or unwhitened, they return only cotton to the soil. And thanks to advances in fiber separation, even mixed-fiber garments can be recycled more effectively.

Cotton is incredibly versatile—94% of us have it in our closets, and chances are you’ve worn it this week. Sustainable cultivation of raw materials is key to making the garment industry truly circular. The U.S. plays a significant role in that process, ranking just behind India and China in cotton production.

But here’s the catch: about 85% of U.S.-grown cotton is exported to be turned into products abroad—then shipped back here to be sold. That’s not really circular. It’s more… oblong.

THE BEST DARN T-SHIRT IN THE LAND

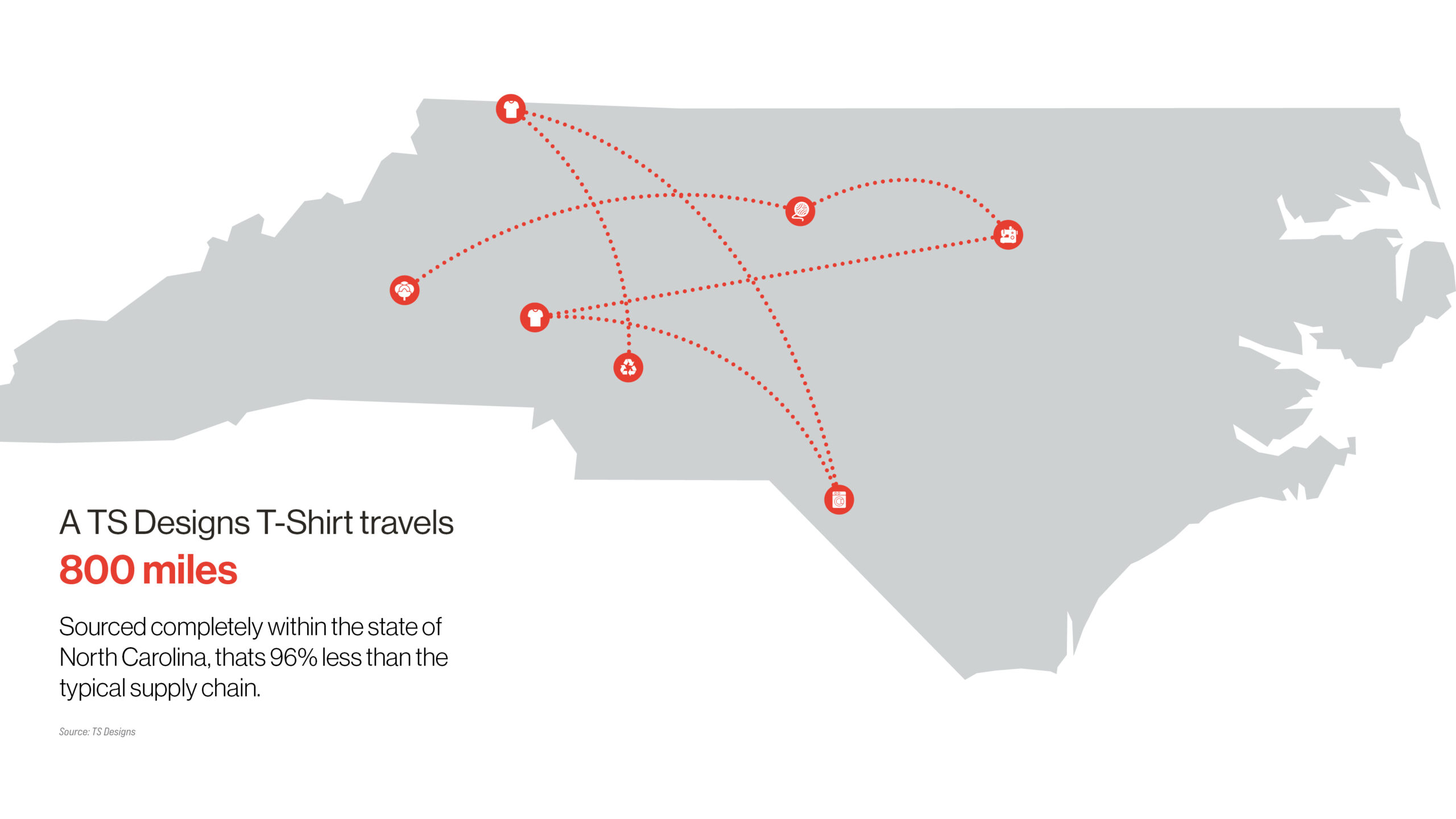

Eric Henry is doing more than his fair share to close the loop on circularity in the apparel industry. Through his company, TS Designs—a certified B Corporation based in Burlington, NC—he’s sourcing U.S.-grown organic cotton and producing what might be the best darn t-shirt in the land. He’s working with a mix of long-standing local cotton processors and garment makers, combined with new, cutting-edge printing and dyeing equipment that makes just-in-time production possible—even at scale.

This approach tackles one of the biggest problems in the apparel industry: waste from overproduction. Eric’s facility already includes technology that can dye and dry garments in a matter of hours. Even more efficient equipment is on the way, along with staff training, to further reduce energy use while increasing output.

Retail isn’t just a channel—it’s a living system sustained by growers, manufacturers, retailers, and service providers. It supports livelihoods and entire communities. And we, as designers and consumers, are part of that system. We now have an opportunity to help regenerate it—to bring back local capabilities and sourcing models that once defined the circular economies we abdicated decades ago.

LOOKING AHEAD

As we look ahead, here are a few reminders to guide us:

Renew local. Circular economies work best when rooted in strong local systems.

Revere our history. The U.S. apparel industry has a deep, proud heritage worth honoring.

Respect the work. Whether it’s a short-term job or a lifelong career, this industry thrives on honest, hands-on labor—the heart of retail, America’s largest employment sector.

Regenerate the industry. Bringing production closer to home helps reduce the miles each garment travels and strengthens our supply chains.

Reconnect to our sources. Just like our food, the origin of our clothing matters. Both come from the earth in their best and most sustainable forms—and both should return to it that way.

Realize your impact. Every choice you make—what your clothes are made of, where they come from—influences whether the system moves toward regeneration or more of the same.

ADDITIONAL RESOURCES

- For more on recycling cotton fiber and apparel, visit Blue Jeans Go Green and Goodwill.

- Learn more about the cotton industry at Cotton, Inc.

- Curios to learn more about Eric Henry and his best darn t-shirt in the land? Visit Solid State Clothing.

- Check out Raleigh Denim Workshop (one of Eric’s favorite-from-afar brands).

- For other Made in the U.S.A. apparel brands, visit Todd Shelton’s blog.

- Get details on Shop! Association and Shop! Ideation in Providence in October 2025.

- Continue the conversation with Eric by emailing or connecting with him on LinkedIn.